Benefits of Green Decortication

Cost Savings

Lower Startup & Operating Cost

Avoids multi-million-dollar decortication plants (tens of millions in startup and operating costs).

Eliminates transportation costs of shipping bulky stalks to offsite facilities.

Reduces labor and fuel expenses with one-pass harvest and processing.

Long-term savings quickly offset the initial purchase price.

Superior Fiber Quality

Cleaner, Stronger, longer Fiber

Elimination of retting prevents decomposition and mold.

Preserves cellulose strength and integrity.

Produces long, clean, high-quality fibers.

Fibers suitable for textiles, composites, and other premium applications.

Avoids discoloration, uneven quality, and weakened structure.

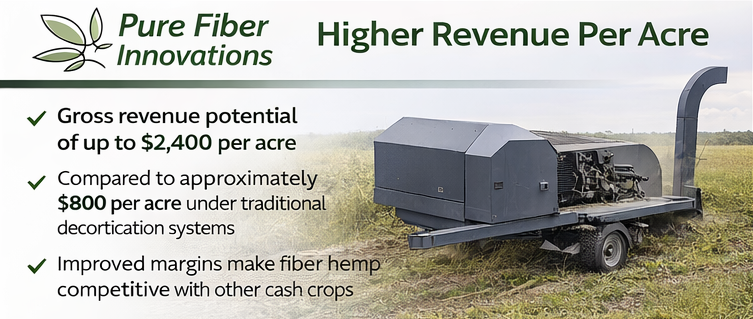

Higher Farmer Revenue

Green decortication boosts per-acre returns for growers

Farmers using traditional decortication gross about $800 per acre.

Green decortication can increase gross revenue to up to $2,100 per acre.

No retting, storage, or transport to an offsite facility means higher efficiency and profitability.

Farmers can sell the finished raw materials directly to the markets. This makes hemp farming financially competitive with other cash crops.

Decentralized Hemp Production

Allows hemp to be grown almost anywhere

Hemp can be grown anywhere — no geographic limitation or need to be close to a major processing facility.

Eliminates transport of raw stalks — lowers fuel, labor, and time costs by processing fiber directly in the field.

Opens opportunity for more farmers — allows regions previously excluded from hemp production to participate.

Strengthens supply-chain resilience — reduces reliance on a small number of central processors.

Encourages regional economic development — keeps more value local and diversifies rural economies.

Expands the national production base — increases fiber availability and supports downstream industries.

Time Efficiency

Faster Harvest & Processing

Eliminates retting, reducing time hemp stays in the field.

Harvests and decorticates 4 acres per hour.

Equivalent to processing 16 tons of stalk per hour.

Removes dependence on weather.

Faster turnaround lowers risk of crop loss and boosts scalability.

Uniform Output

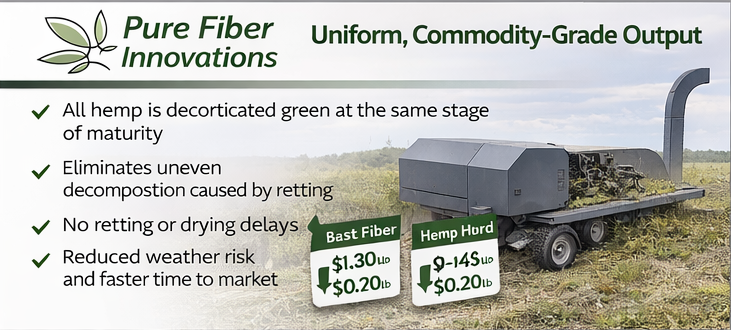

Consistent Hurd and Fiber

All hemp decorticated green at the same time.

Eliminates uneven decomposition caused by retting.

Creates predictable, standardized fiber quality.

Green-decorticated fiber sets the standard for hemp as a commodity.

More Affordable Raw Materials

Lower prices for fiber and hurd fuel industry growth

Hemp bast fiber price could drop from $1.30/lb to $0.30/lb.

Hemp hurd price could drop from $0.45/lb to $0.20/lb in bulk.

Lower raw material costs make hemp products more competitive in mainstream markets.

Reduces barriers for hemp entrepreneurs and stimulates market growth.

Affordable, high-quality materials will fuel innovation and expansion across hemp industries.